STYLEman365 ERP is a fifth generation application designed specifically for the needs of apparel and footwear companies. It has configurable dashboards highlighting appropriate KPIs which are updated in real time, and can also be pinned so that they are visible throughout the application. Some of the main functional areas of STYLEman365 ERP are described below.

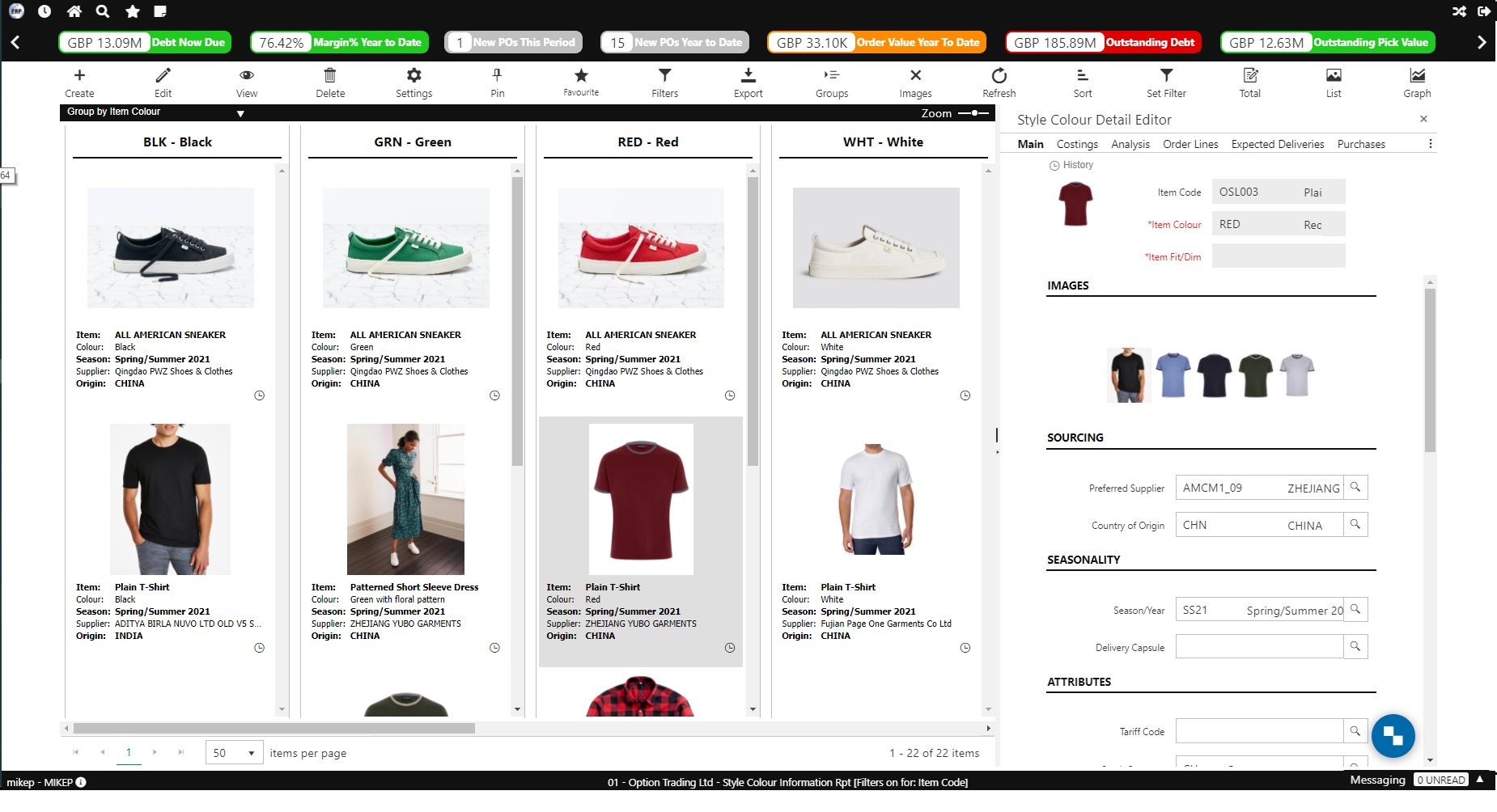

Product Setup

STYLEman365 ERP has been designed from the outset to cater for the production and distribution of items with a colour/size matrix. The system also allows the use of a second size dimension such as leg lengths, bra cups, or shoe widths if required. It’s a multi-level solution that allows for data to be entered at any level in the matrix so, for example, budget costings, costs or prices can be entered at any level of style, colour, fitting or size as appropriate.

If you’re a larger organisation with multiple trading companies, you’ll appreciate the Central Style Maintenance functions where you centrally control all aspects of a style except those that the individual marketing companies are allowed to modify (for example, descriptions, costs or prices).

STYLEman365 ERP supports a number of different pack options including: single colour/single size, single colour/multi-size, multicolour/multi-size, multi-style/colour pre-packs, merchandise packs and promotion sets.

Product Costing

STYLEman365 ERP uses flexible costing formats, incorporating comprehensive calculations, to allow you to build up the standard costs of a style using the components you use in your business. The component parts of a style costing can be built up automatically from freight, quota and duty tables in STYLEman365 PLM, with additional items such as overheads or margins either calculated on a percentage basis or entered manually. STYLEman365 ERP also supports costing at the warehouse level, to cater for the differential costs when holding stock (say) within and outside the EU.

The initial product costing is used as a standard base and all inbound purchase order actual values are recorded and compared to the base costing for real margin analysis.

CRM - Customer Relationship Management

All contacts made to your organisation from a customer can be recorded and analysed in STYLEman365 ERP. Each occurrence is given a contact analysis code and allows the recorder to write a detailed description of the event and either close it immediately (with a contact resolution analysis code) or leave it outstanding with an expected resolution date, time and responsibility. At this point, the contact record may be left with the operator that recorded the call or reassigned to another operator, in which case it will appear in their list of Tasks.

Sales Order Capture

STYLEman365 ERP uses Sales Order Capture as the heart of a multi-channel business strategy. Demand can arise from your wholesale customers, your own retail and franchise stores, concessions, distributors, and e-commerce sales. They can be entered into STYLEman365 ERP in a variety of different ways: imported from spreadsheets, EDI, manually through the efficiently simple Order Entry program or from interfaces to your e-commerce and retail merchandising systems. They can also be entered directly through STYLEman365 B2B, an extension to STYLEman365 ERP specifically designed for customers, front line sales staff, agents and distributors

The system supports both forward and stock orders, and provides real time availability quantities so you can reliably inform the customer of what’s available today, next week, next month etc. Online credit checking provides immediate feedback on the state of the account during order capture.

STYLEman365 ERP provides a comprehensive suite of order book management tools that include:

- Mass order duplication

- Single order duplicate and change

- EDI gateway

- Contract call-offs

- Range rationalisation to switch products after the selling period

- Multiple item substitutions

- Customer cancellation letters

If you have multiple brands with different sales people selling into one account with different commissions and trading terms, STYLEman365 ERP order processing takes care of it.

Stock Allocation

Finished goods inventory is reserved against sales orders using either bulk automatic or manual allocation. Bulk allocation uses rule sets to define which orders should be selected for allocation by use of a multitude of selection criteria (for example, customer types, countries, brands, groups or salesman). Once a pool of sales orders has been selected, they will be allocated by priority and the delivery dates on the sales orders. Both trial and actual run options provide the user with a choice of reports detailing exactly which orders did and did not get allocated with reasons why. Facilities exist to allocate all styles received in a defined date range and automatically apportion the stock quantity to the customer’s order quantity where a shortage occurs. Manual allocation allows the user to choose exactly which order lines should be allocated and is particularly useful when stock is being run down and multiple order lines need to be modified to spread the allocation. STYLEman365 ERP also supports soft allocation where the expected delivery of a sales order line is continually calculated to allow operators the ability to predict to the customer when the order could be satisfied.

Picking

Picking tickets are generated for sales orders using either bulk automatic and manual allocation, and orders can be picked from either an allocated or open status. Bulk picking uses rule sets to define which orders should be selected for picking by use of a multitude of selection criteria (for example, customer types, countries, brands, groups or salesman). Both trial and actual run options provide the user with a choice of reports detailing exactly which orders did and did not get picked with reasons why, which can include customer over credit limit, customer over terms, minimum order pick percentage and minimum percentage of key sizes. Manual picking allows the user to choose exactly which order lines should be picked. The warehouse(s) can contain both pick face and bulk locations if required and automatic replenishment of stock from the bulk to pick face locations may be triggered during a pick run. Bulk summary reports can be produced where a bulk pick is performed to satisfy a packing station. Warehouse operations are supported by using paper-based documentation, or STYLEman365 WMS provides paperless warehouse operation including facilities for optimised parallel picking of small (e-commerce) orders.

Packing

For Pick and Pack operation, carton packing can be performed using scanners with the immediate production of a packing list and carton label. If orders have been picked well in advance of the delivery requirement they can be packed away using the “Pack & Hold” facility. This allows all documentation to be produced and the goods to be located in a holding area ready for despatch, to help reduce warehouse activity at peak times.

Despatch

The despatching program in STYLEman365 ERP allows for a number of different options. Multiple picking tickets can be consolidated onto one despatch and multiple despatches can be combined onto one invoice. Invoices can be created in the ledger immediately at despatch or later as required by the customer. Multiple invoices can be consolidated up to a weekly or monthly invoice for the customer. Documentation produced at despatch includes despatch notes, carton labels, carrier consignment notes, ASNs and commercial invoices, and integration into carrier systems is supported.

Sourcing Products

STYLEman365 ERP supports items which are purchased from third party factories, manufactured by third parties using some or all of the materials that you supply (CMT) or manufactured in your own factories. All three types of sourcing order can be raised manually, from Forecasts, from Sales Contracts or from consolidated and uplifted sales via the suggested purchase orders module.

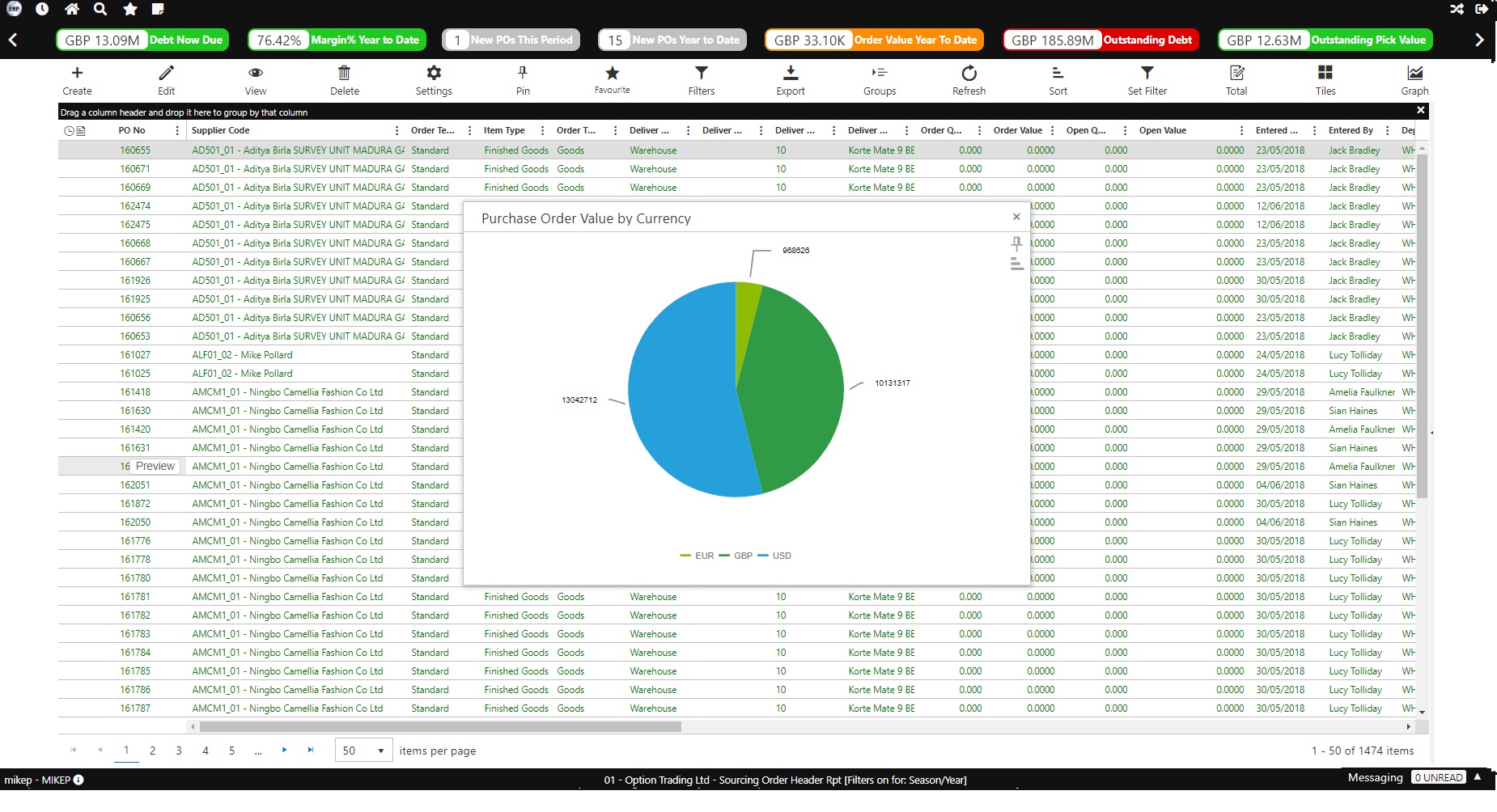

Purchasing

A style purchase order can contain multiple styles with multiple delivery dates if required. The critical path attached to every style purchase order ensures the relevant personnel are notified when an event becomes imminent. Full delay history is maintained with reason codes and number of days for later supplier performance analysis.

Style purchase orders can be raised as unconfirmed, requiring authorised personnel to approve and confirm before sending to the supplier.

Multiple currency costing with budget and actual exchange rates allow you to accurately compare your budget style costs to the actual receipt costs.

Purchase orders from multiple suppliers can be consolidated and put onto one shipment for simple inbound tracking and apportionment of freight invoices. Containers, bills of lading and letter of credit details can all be recorded.

Stock receipts and GRN generation can be performed using Wi-Fi scanners in multiple warehouses and locations.

STYLEman365 B2S is a supplier portal, offering selected suppliers a gateway into STYLEman365 ERP in order to manage their own orders, progress them and give a breakdown or what is despatched. More information here.

CMT Sourcing and Manufacturing

STYLEman365 ERP supports both CMT and full Manufacturing; the process starts with holding the details of component items (fabrics, trims, yarn, packaging etc), both at a total (meterage/yardage) level as well as individual rolls and dye lots. Interim sub-assembly components (pocket bags, bra straps etc) are also supported as both inventory and Bill of Material items. Raw Material items have their own hierarchy that corresponds to finished goods, of Item, colour and dimension.

The Bill of Materials (BOM) is structured such that components are held at the lowest level at which you want to track usage and consumption. For instance, a high-value fabric may be tracked at style/colour/size level whereas a clear polybag would be set up at the style level. This makes it both highly accurate and easy to maintain. Component items on the BOM can be raw material items, sub-assemblies or even other finished goods items (styles). Powerful facilities exist to mass-duplicate, duplicate and change, substitute materials immediately or in the future, and track full BOM change history.

Material Requirements Planning (MRP) can be initiated in a number of ways in STYLEman365 ERP: from Style Forecasts, from Sales Contract or Sales Orders or from Purchase/Production/CMT Orders. The resulting plans offer a time-phased demand plan for each component, taking any existing stock and purchases into account, minimum stock levels and reorder quantities. The demand plan can be adjusted if required, and the suggested quantities for raw materials and multi-level subassemblies can be automatically purchased. The resulting material purchase orders are linked and tracked against the parent production or CMT order.

Raw material purchase orders can contain multiple raw material items with multiple delivery dates if required. The critical path attached to every material purchase order ensures the relevant personnel are notified when an event becomes imminent. Material purchase orders can be raised as unconfirmed, requiring authorised personnel to approve and confirm before sending to the supplier. STYLEman365 ERP supports full Case/Roll control and the details of each unique Case/Roll can be recorded at the time of receipt, allowing unique bar-coded labels to be generated.

As product comes off the production line it can be scanned into cartons and a carton label will be generated. As a carton is received into the stores it can be assigned onto a customer shipment. A shipment can be one or many orders grouped together ready for despatch.

Despatching is a simple process where the shipment number is selected and the weight, cube and bill of lading details are entered. Full traceability is maintained from the shipment header to the sales orders, carton contents, packing lists, despatch notes and invoices. Invoices can be raised and emailed automatically.

STYLEman365 ERP uses flexible costing formats to allow you to build up the standard costs of a style using the components you use in your business. The component parts of a style costing can be built up automatically from the Bill of Materials and the Bill of Labour (Routing), with additional items, for example overheads or margins, either calculated on a percentage basis or entered manually.

On the Bill of Labour (BOL), STYLEman365 ERP allows operations to be attached to the style at the most appropriate level and its clever maintenance program is designed for rapid input of the BOL. An operation that is the same regardless of colour or size will only need entering once and is automatically inherited by all variants within the style.

STYLEman365 ERP can integrate into several different graphical planning tools, providing quick, simple and visual means of scheduling and loading orders directly against factories, production lines, machine types or any other key manufacturing resource. Planning Boards can be loaded directly from STYLEman365 ERP with styles, orders and material production orders, which may then be visualised on the board, changing colour dynamically as they are rescheduled to indicate early, on-time or late completion.

Facilities exist to allocate (reserve) material stocks to production/CMT orders as they become available. Allocation can be performed at the production order level for all materials or at the material level for all production orders.

Materials are issued to the production floor as required. Issuing is a Wi-Fi scanner-based activity where rolls or boxes are scanned and automatically moved into WIP. An ad-hoc issuing program allows the stores to send additional items required by production to WIP. Issuing materials to a third party CMT order allows all the materials sent to the sub-contractor to be tracked for accurate consumption.

The STYLEman365 ERP Work In Progress (WIP) module allows production to be tracked using line or modular production methods. Bar-coded stickers are produced with each operation and SMV to the bundle quantity of your choice. Scanning of both the operator and individual operations stickers allows detailed analysis of the operators’ performance and efficiency. This analysis rolls up to the module/line/factory levels.

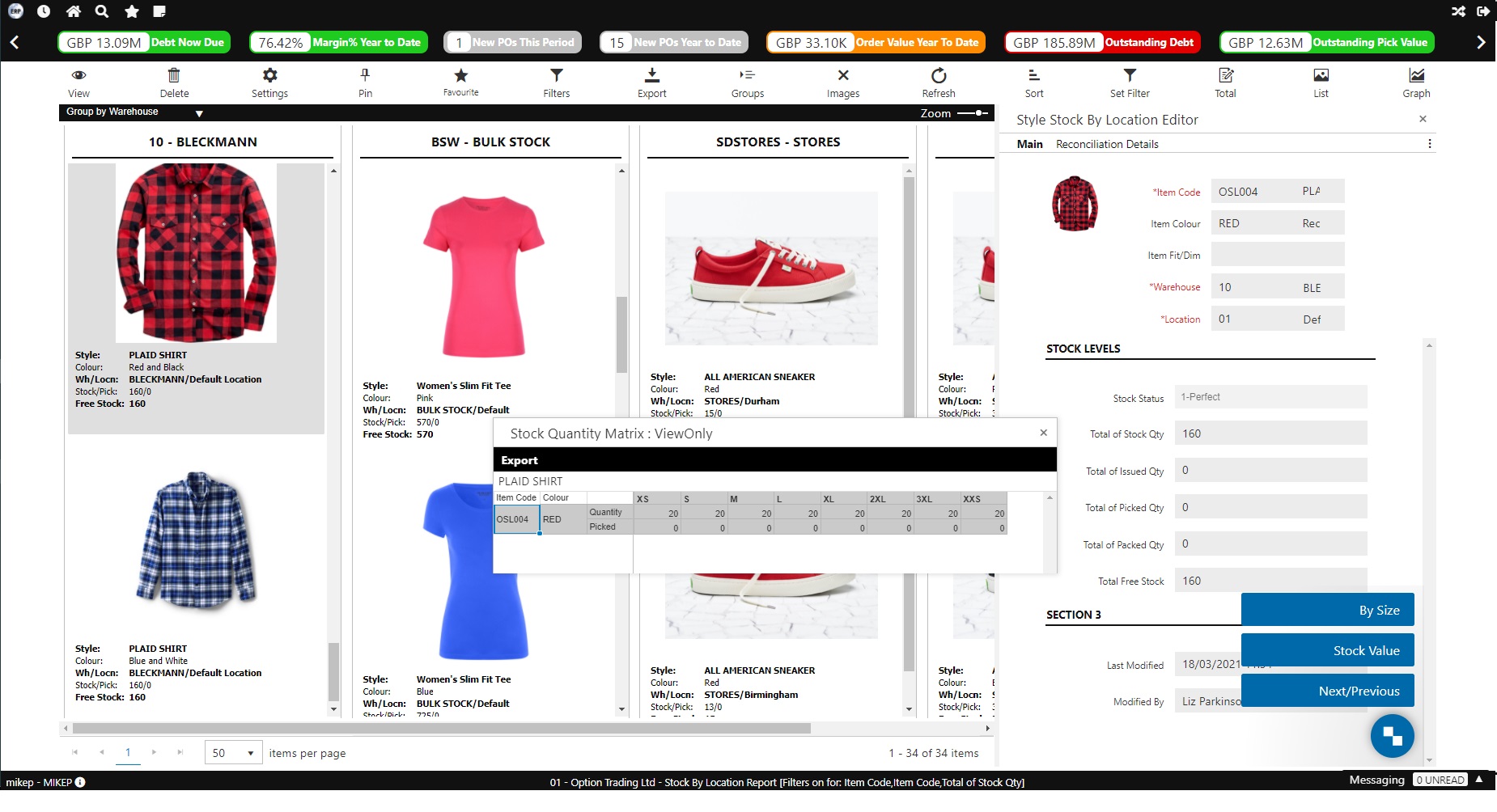

Warehouse Management

Warehouse Management in STYLEman365 ERP can be controlled by a paper-based system, or by STYLEman365 WMS a Wi-Fi based warehouse management module that allows paperless control of warehouse activity. Facilities exist in STYLEman365 ERP to manage putaway rules, monitor warehouse and operative activity and analyse operative performance.

Returns Processing

The STYLEman365 ERP returns module starts with the issuing of a return authorisation to the customer and this is typically a customer service function. Facilities exist to record as much information as the customer can give regarding the returns and to generate the next sequential authorisation number.

The warehouse is normally the next link in the return chain. They can see details of authorisations that have been issued but have not yet arrived at the warehouse. As goods come in, the warehouse can enter a goods returned note into STYLEman365 ERP. Ideally this is related to an authorisation but this is not mandatory.

The warehouse may have time to fully QC the returns and assign a quality code (perfect/seconds/scrap) to the item along with a reason for the return. If the warehouse does not currently have time for the full QC process, they can still book the goods in for later QC.

The next link in the chain is the office to create a credit note. They can see all outstanding authorisations and GRNs in the warehouse. Once a GRN is fully QC checked, it can be credited (a credit note can also be created without a GRN if required). If the credit office can relate the goods returned to an original invoice, this will help with pricing of the credit note. If the original invoice is not known, STYLEman365 ERP will locate the lowest price available for that customer over a specified time.

Credit notes can also be created for extra values (for example, carriage) and non-stock returns still related to the original product invoiced (such as overcharges or short deliveries).

STYLEman Demo

If you’d like a personalised product demonstration for your chosen STYLEman product(s) then please click below.

More information

We’d be delighted to answer any questions and discuss your requirements further; please call +44 (0)116 291 6666 and sales@styleman.com